R&D Advantage

Pingshan

● Located in Shenzhen Pingshan Biomedicine Innovation Industrial Park

● Over 7000 ㎡ R&D Lab

The R&D platform with a total investment of more than 100 million RMB can provide a full range of services for chemical drug pharmacological research. At present, there are several innovative drug projects with clinical acquiescence, and dozens of projects are being carried out.

R&D Advantage/Core Technology

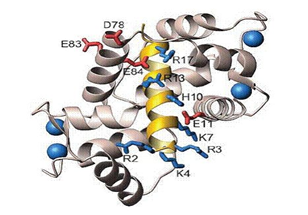

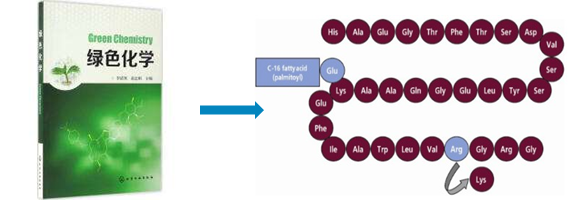

Core technology of complex peptide chemical synthesis

Long peptides (30-60 amino acids), complex long peptides (with side chains), Multi-cyclic peptides, unnatural amino acid peptides, Peptide-SiRNA, Peptide-Protein, Peptide-Toxin, Peptide-Nuclide…

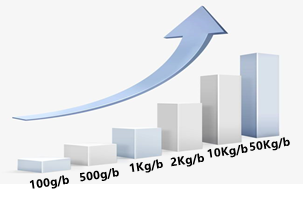

Core technology for step-up amplification of peptide manufacturing

Batch: from 100g/ batch to 50kg/batch

R&D Advantage/Technical Team

Core team over 20 years experience on development of peptide drugs.

A technical team gathered from various fields such as process development, analysis, RA, and GMP production.

Professional background covers pharmaceutical chemistry, pharmaceutical preparations, organic chemistry, analytical chemistry, bioengineering, biochemical technology, pharmacy or other related majors.

Rich experience in peptide synthesis, macromolecular drug development, pilot scale and quality management, mastering the know-how of peptide products from laboratory to industrialization, with the ability and experience to solve various difficult problems in the development of peptide drugs.

Brand New/Core Technology

Rapid application of peptide frontier technology

● SoluTag- Modification technique improving the solubility of peptide fragment

● NOCH oxidizing technique

● Continuous flow peptide synthesis

● Online Raman monitoring technique for solid phase synthesis

● Enzyme catalyzed unnatural amino acid synthesis technique

● Targeted site modification technique for peptide catalyzed by photo irradiation

Industrialization Advantage

Pingshan,Shenzhen

Finished Products, Shenzhen JXBIO, 4 preparation lines in compliance with GMP regulation.

Xian’ning, HuBei

APIs, Hubei JXBio, 10 production lines.

9 production lines in compliance with FDA and EDQM, has become the largest manufacturers of chemically synthesized peptide APIs in China.

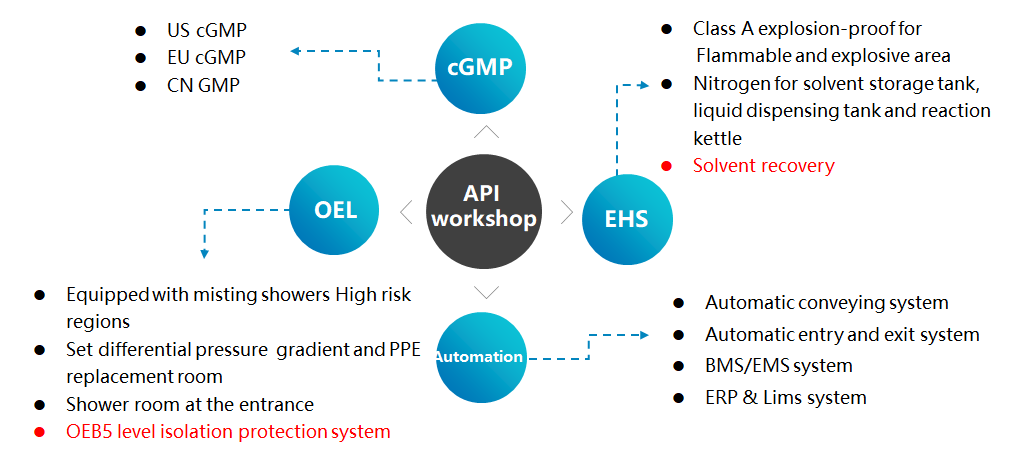

API Workshop - Advanced Design Concept

APIs Manufacturing Facilities

Synthesis/cracking reaction system

● 500L, 10000L Enamel reactor(LPPS)

● 20L,50L, 100L Glass reactor (SPPS)

● 200L-3000L Stainless steel reactor (SPPS)

● 100-5000L Cleavage reactor

Production Capacity Distribution

|

production line |

products |

batch |

Annual output |

|

5 ProductionLines |

GLP-1 |

5kg-40kg |

2000kg |

|

4 ProductionLines |

CDMO |

100g-5Kg |

20 Projects |

|

1ProductionLines |

Intermediate and cosmetic peptides |

1kg-100Kg |

2000kg |

|

The vacant land in the factory area is 30 acres, and the expansion space is huge. |

|||